We ensure adherence to the best quality standards to ensure that the pipes being manufactured have high tensile strength and are capable of withstanding adverse whether conditions. The pipes being supplied to the clients are tough in construction, wear and tear resistant and have a high leak proof capability thus ensuring a long service life.

We ensure adherence to the best quality standards to ensure that the pipes being manufactured have high tensile strength and are capable of withstanding adverse whether conditions. The pipes being supplied to the clients are tough in construction, wear and tear resistant and have a high leak proof capability thus ensuring a long service life.

The products being manufactured in our works are tested at every stage for quality in accordance with the specifications prescribed by the Indian Standards Institution.

Te products are tested to determine and ensure the following parameters:

• Smooth edges

• Durability

• Finishing

The quality of RCC pipes is determined by the Hydraulic pressure test and the Three edge bearing test.

The Hydraulic Pressure Test is conducted by applying water pressure from a pump to the pipe in the state of having the pipe covered on all sides to find the pressure that the pipe withstands before the pipe leaks. The pipe is approved for quality if the pressure obtained by the test is compatible with the ISI specifications.

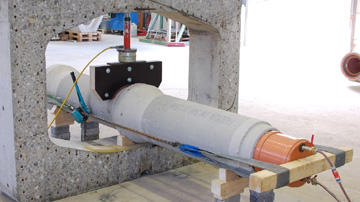

The Three Edge bearing Test is conducted by applying load on the pipe through a jack until the pipe gets cracked. The pipe is approved to have passed the test if the load conditions specified according to the IS specification are satisfied.